AF200X FEP Wire

FEP, also called Fluorinated Ethylene Propylene, has excellent electrical properties, a wide operational working temperature range(up to 200°C.), high chemical and UV resistance, low coefficient of friction and low flammability. Due to these superior attributes, FEP cables are widely used in medical, electrical, lighting, chemical and aerospace industries, among others.

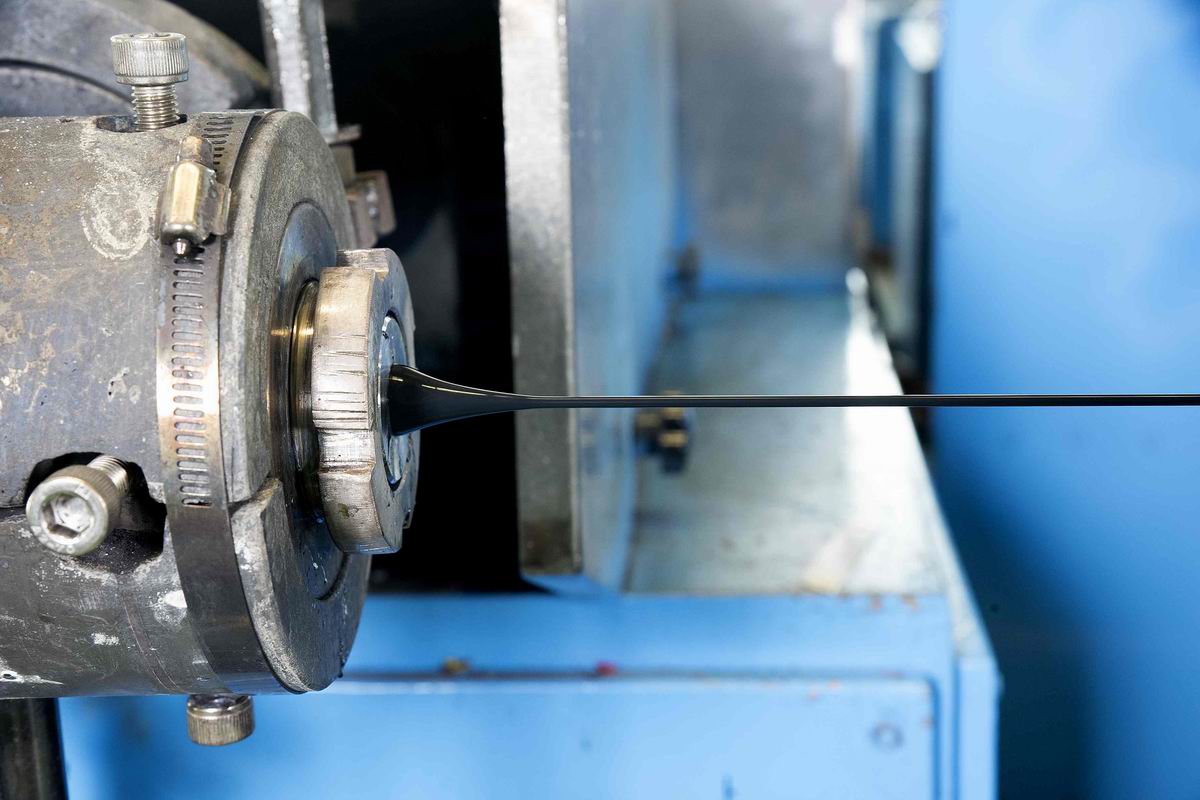

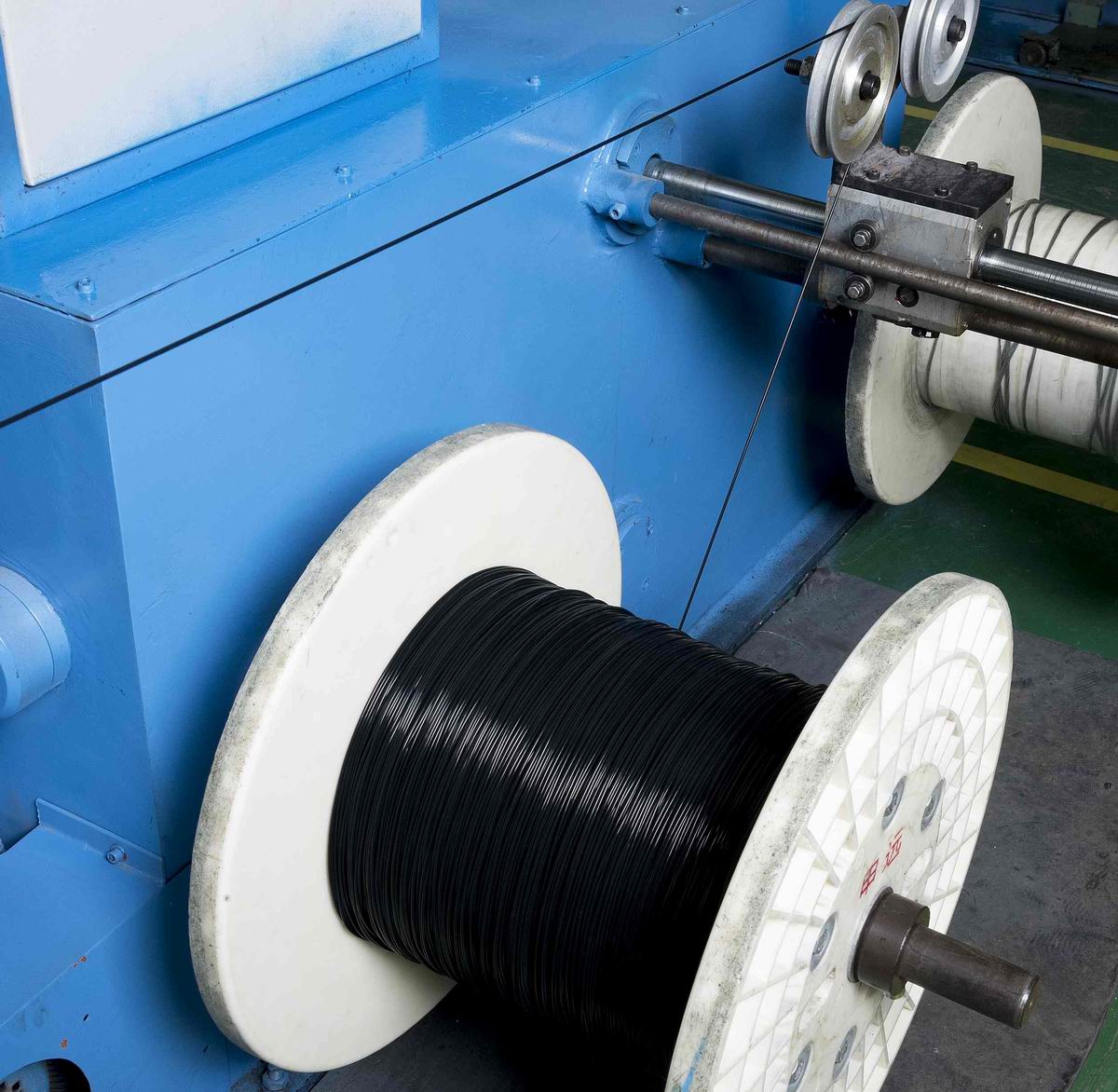

We use a solid and stranded conductor. The most common conductor is silver plated copper and Tinned copper.

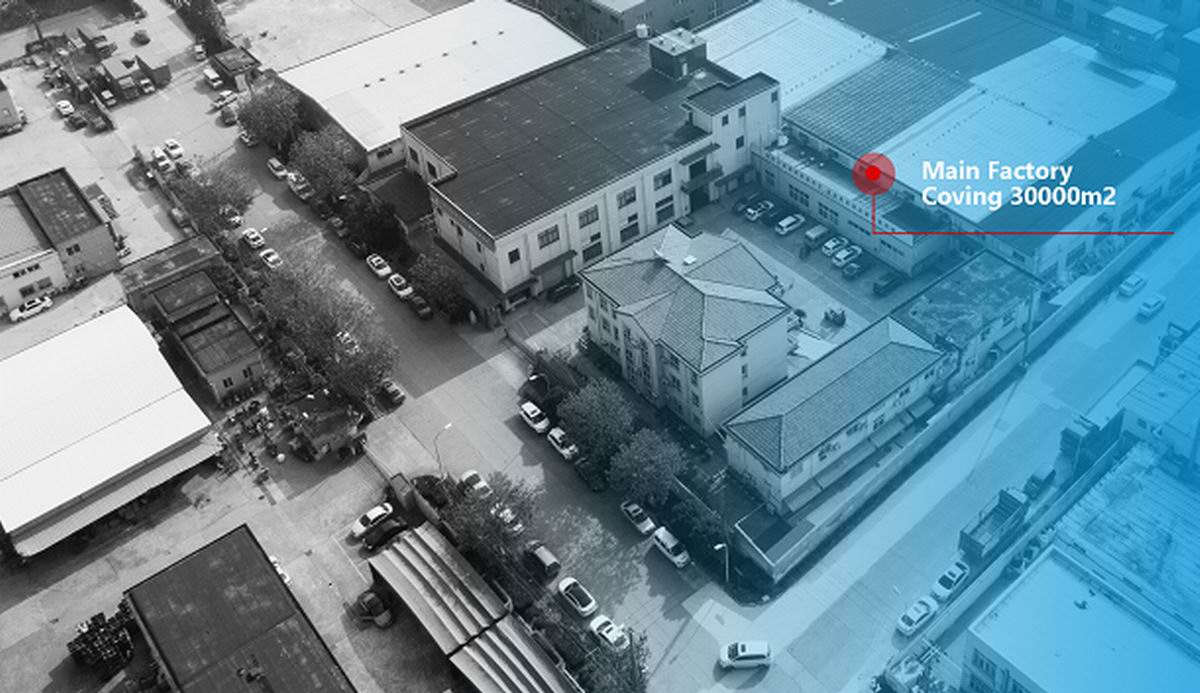

For now Shanghai Xutong have total 36 sets FEP production lines with annual capacity of 150,000 KMS, which dramatically pull down the cost and enable us to provide customers with extremely competitive price, especially for the partners who are interesting in being our Agent in local places of the world.

Over 80 sorts of UL Certificates wires for selection,meeting your requirements.

For FEP wires we have UL certificated wires as following:

FEP Insulation wire 200 ℃

UL1330 UL1332 UL1333

UL1371 UL1538 UL1577 UL1591 UL1592

UL1723 UL1887 UL1901

PFA Insulation wire 250 ℃

UL1707 UL1708

UL1709 UL1726 UL1710 UL1716 UL1727

UL1857 UL1860 UL1858 UL1859 UL1882

UL1929 UL1930 UL1933 UL10110

UL10129 UL10362 UL10485

UL10486 UL10503 UL10142

PTFE Insulation wire 260 ℃

UL1164 UL1180 UL1198 UL1199

UL1212 UL1213 UL1570 UL1584

UL1815 UL10393 UL1659

Annual capacity of other High-temperature wires as below:

1.PFA/FEP/ETFE/PEEK wires:400,000 KMS

2.PTFE tape lapping wires:18,000 KMS

3.Extremely -soft Silicone rubber wire:72,000 KMS

4.Silicone rubber wires with high voltage:20,000 KMS

5.High temperature wires with Shield:28,000 KMS

6.MGT fiberglass lead wires:10,000 KMS

7.EV wires:200,000 KMS

8.Silicone rubber wires with braided fiberglass sheath:18,000 KMS

9.Multi-core cables:40,000 KMS

|

Cross section |

Conductor structure |

Insulation thickness |

Average outside diameter |

20 ℃ conductor DC resistance |

Packing length |

|

0.014 |

7/0.05 |

0.15 |

0.45 |

1454 |

500 |

|

0.035 |

7/0.08 |

0.15 |

0.60 |

568 |

500 |

|

0.05 |

7/0.10 |

0.15 |

0.60 |

356 |

500 |

|

0.08 |

7/0.12 |

0.20 |

0.78 |

245 |

500 |

|

0.12 |

7/0.15 |

0.25 |

0.95 |

163 |

500 |

|

0.20 |

7/0.20 |

0.25 |

1.10 |

90.4 |

500 |

|

0.35 |

19/0.16 |

0.25 |

1.30 |

53.1 |

200 |

|

0.50 |

19/0.18 |

0.25 |

1.40 |

40.1 |

200 |

|

0.75 |

19/0.23 |

0.25 |

1.70 |

24.6 |

200 |

|

1.0 |

19/0.26 |

0.25 |

1.80 |

20.4 |

200 |

|

1.20 |

19/0.28 |

0.30 |

2.0 |

16.6 |

200 |

|

1.50 |

19/0.32 |

0.30 |

2.25 |

12.7 |

200 |

|

2.0 |

19/0.37 |

0.30 |

2.45 |

10.0 |

100 |

|

2.5 |

19/0.41 |

0.40 |

2.80 |

7.43 |

100 |

|

4.0 |

37/0.37 |

0.40 |

3.40 |

4.88 |

100 |

|

6.0 |

37/0.45 |

0.50 |

4.20 |

3.30 |

100 |

|

8.0 |

133/0.28 |

0.50 |

5.20 |

2.30 |

100 |

|

10 |

133/0.32 |

0.50 |

5.80 |

1.82 |

100 |

|

16 |

133/0.39 |

0.60 |

7.00 |

1.22 |

100 |

| Note: According to the agreement between supply and demand, you can produce other specifications of the product. | |||||